Why 3D Scanning

Why use 3D scanning? Who is going to benefit? The better question would be why not use 3D scanning?

- As the humble Maker, you may be asking yourself how 3D scanning will help you to achieve your goals. As an example, imagine you had a great idea for a dog helmet that your beloved pet could wear, but none of your dogs will give you the time of day to sit for hours while you play with clay on their head. Enter 3D scanning. If you could have a 3D representation of the dog’s head, you would be able to make the helmet match perfectly in the digital world before bringing it to life. On the other hand, if you were able to convince your dog to sit still for one 6 hour period while you created the perfect headwear, that hand-made item could be 3D scanned so that Fido never has to sit through the indignity again.

- Info Link: http://www.3dscanco.com/about/3d-scanning/benefits.cfm

- In business, at any point in a typical manufacturing cycle, 3D scanning technology can be utilized resulting in saving time, money and material. 3D scanning results in higher quality, better fitting parts that are less costly to manufacture. THe short short version: anyone in manufacturing, engineering, design, development, surveying or testing can benefit from 3D scanning.

To sum it up, 3D scanning will help you to:

- Quickly capture all of the physical measurements of any physical object

- Save time in design work

- Ensure parts will fit together on the first try

- Capture engineering optimizations inherent in manufactured parts

- Utilize modern manufacturing on parts that were originally manufactured before CAD

- Compare “as-designed” model to “as-built” condition of manufactured parts

Manufacturing Cycle

Concept Phase

When an item is being conceptualized, it helps to use physical objects to develop the idea. This has previously been done by an industrial designer using clay or foam to bring the idea into the three-dimensional world. In this phase, 3D scanning can be applied by digitizing objects and using them as renderings in concept illustrations.

Design Phase

3D scanning can be used in this phase by starting with a physical object and using it to design a CAD model, otherwise known as reverse engineering or reverse modeling. Oftentimes, additional items need to be designed around or made to fit with an initial object. These mating parts can also be scanned and incorporated into the digital design, resulting in parts that will fit better more consistently. By utilizing reverse engineering, new designs can easily incorporate and improve upon the already manufactured part.

Prototype Phase

At the prototype phase there are a couple ways in which 3D scanning is beneficial. The most common difference between the old and new ways of prototyping is that the use of 3D scanning will reduce the number of prototype design cycles that are often necessary. A part designed using 3D scan data often only requires one or no prototypes since it is designed with precise measurements of the physical world. 3D scanning can also be used in combination with prototyping to scale physical objects. By using 3D scan data, a physical object can be translated directly to the engineering phase of a project and moved on from there.

Production Phase

3D scanning can be used to capture changes to tooling or parts that occur on the shop floor. Tooling is often “hand tuned” to achieve the final desired look and finish of a part. Using 3D scanning, hand modifications and optimizations can be transferred from tool to tool to ensure all manufactured parts match after production. 3D scanning can also be used to analyze and characterize tool wear during production, and if used correctly, to predict or eliminate tool failure. In the event of tool failure, 3D scan data can be used to recreate the optimized part.

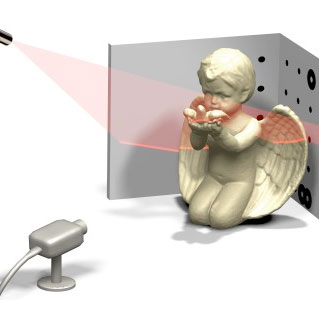

3D Scanners

There is a huge range of costs and qualities when it comes to your own 3D scanning. Unless 3D scanning is going to be a large part of your life, it is definitely easier to go to your friendly neighborhood professional for a one or two time scan.

Free

- Free – 123D Catch – an app for iPhone, Android and Windows phone

Hobby

- $550 MFS1V1 3D Scanner

- $499 Skanect Structure Sensor

Professional

- $19,800 Artec Eva

- $14,200 Artec Eva Lite

- $27,000 Artec Space Spider

Frequently Asked Questions

How accurate is the 3d scanned digital model going to be?

- Accuracy depends upon the item complexity, the quality of the scanner, and the expertise of the post processing individual. Most scans easily create a cohesive 3d model, but with more nooks and crannies there may be holes in the model that require the finesse of an experience individual to fix.

Can I scan both inanimate and animate objects?

- Inanimate objects are easier to scan because the process can take up to five minutes or longer depending on the complexity of the item. Animate objects, such as people, can be done easily as long as the person can stand still. In fact, we have our 3D Selfie Station at Deezmaker! If you can get other living critters to stand still for the required amount of time, scanning is as easy as 1, 2, 3!