The Ultimate Tool for Makers

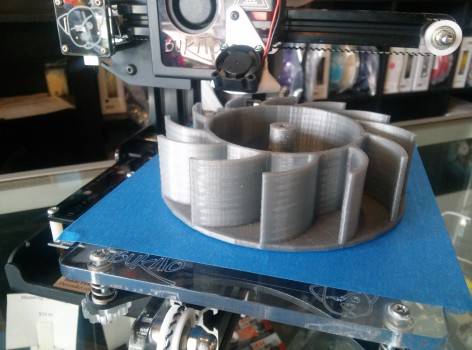

Home 3D printers mostly use a process called, alternately, filament deposition manufacturing (FDM) or fused filament fabrication (FFM). A plastic, nylon or similar filament is melted and then deposited onto a smooth surface (called the print bed) by the printer extruder. The print bed is lowered, or the extruder raised, and the object is built up layer by layer to create the digital file as a tangible item.

If you’re wondering about what 3D printers can do, here are a few examples to think about:

Affordable prototyping to get it right

Affordable Prototyping

The cost of filament can be as low as $0.03 per gram (PLA, ABS), but you would be hard-pressed to find a 3D printing shop that does work for you at cost. After all, they do have to make sure that it is set up correctly and prints to specific specifications. If a print is not correctly finished by the machine due to any issues, such as the power going out, the shop has no choice but to eat the cost. Printing on your own will make things much more affordable in the long run. Plus you get the fun of watching your design manifest in front of your own eyes.

Example: 3D printing an item weighing 30 grams

- At home: cost = 30g x $0.03 = $0.90

- Professionally done: Anywhere between $10.00 to $50.00

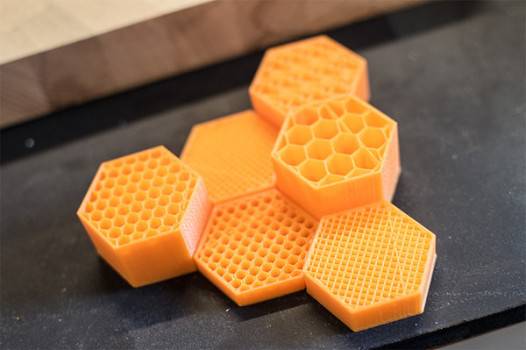

Take control of speed with the infill

Fast Printing

If you don’t have the time to wait for a professional to print your object, and instead need something in your hand as fast as possible, with your own 3D printer there is no queue or wait time. In fact, if you set a large layer height you can watch as your printer lays layer after layer of filament with alacrity. You also are granted greater control over the infill of your print, which means you can lay down the least amount of material necessary to keep your model from collapsing in on itself, whereas a professional shop is going to use more infill to limit the possibility of issues arising.

Experimentation

It’s nice to have a perfect, finished product in your hands that you bought already made, but the need to experiment is great in many of us. Maybe you want to try 3D printing chocolate, or wax to make your own unique candles. The sky is the limit for the avid hobbyist. Because it’s your own machine, you can quickly switch between PLA, ABS, and PC or modify your printer with a whole new system of extrusion. In fact, the most inexpensive open source machines are wonderful for this. If you happen to ruin an extruder or mangle one of your stepper motors, there are spare parts readily available. You can’t make an omelet without breaking a couple eggs afterall.

Custom 3D Printed Guitar – Creator Link

Total Customization

We’re all unique people with different needs; why should we be limited to all of our physical items being the exact same as everyone else? Although it might be easier to order an item, such as a phone case, from Amazon Prime today, perhaps your personal inclinations are different from the options are are currently available. No, you want the shapes, sizes, and colors to fit you, your needs and your personality perfectly. Why should only celebrities get to be unique? Enjoy the luxury of printing things, your way.

Practical Use

Some people would rather buy everything they want, and never have a second thought about how they could have easily made that same object themselves. Makers might want to buy some things prefabricated, but in the end they are Makers and are more satisfied by do-it-yourself projects. There is a great deal of pride in holding up an object or accessory that everyone has been using or complimenting and getting to say loudly, “Oh that? Yea, I made that,” to the “oohs,” “ahhs,” and “no way” comments that erupt around you. And the nice thing is that you don’t have to start from scratch as Makers everywhere share their designs for anyone to print. And you still get to say that you made it.

Interested in More Examples?

Embark on a journey into open source technologies including 3D printers, Arduinos, robots and wearable tech with The New Shop Class and discover just how much you can create. This book is perfect for aspiring scientists, makers, teachers, students, and anyone who wants a guide to the vast and expanding world of makers and their tools and inventions.